Orienson Secures Key Project with Frencken Group

Recently, Dongguan Orienson Hardware & Electrical Co., Ltd. (hereinafter referred to as "Orienson") announced exciting news of a major cooperation: leveraging its advanced equipment configuration and solid precision machining capabilities, the company has successfully undertaken a new project for the customized production of precision hardware components for Singapore-based Frencken Group (also known as "Fengxing Group"). This collaboration not only marks the successful implementation of Orienson's equipment upgrade achievements but also represents a crucial breakthrough in its efforts to connect with the global high-end manufacturing supply chain and expand high-value-added businesses. Meanwhile, it provides strong support for Frencken Group to optimize its production support system in the Asia-Pacific region.

Headquartered in Singapore and listed on the Main Board of the Singapore Exchange, Frencken Group is a global integrated technology solutions provider with over 60 years of industry experience. Its business footprint spans more than 50 countries worldwide, boasting 18 operating bases and 16 design and manufacturing centers. The group offers customized technical solutions for multiple high-value-added sectors, including healthcare, semiconductors, analytical and life sciences, industrial automation, and automotive. Its clients are mostly well-known global multinational enterprises, which have stringent requirements for the precision, stability, and delivery efficiency of components. Particularly in the production of products such as patient bed components for medical CT/PET scanners, precision parts for semiconductor wafer manufacturing, and automotive transmission filters, supporting manufacturers are required to possess top-tier stamping capabilities and quality control systems.

Orienson's success in winning this new project with Frencken Group is inseparable from its recent equipment upgrading and transformation. It is reported that Orienson has newly added 3 Komatsu stamping presses, including 2 units of 80-ton models and 1 unit of 45-ton model, which can meet the machining needs of precision hardware parts of different specifications. This series of presses is equipped with plunger-guided slide technology, which can extend mold lifespan by at least 30%. Additionally, the Press Line Simulator's mold interference inspection function enables the generation of optimal motion trajectories, while the servo die cushion achieves the dual advantages of high formability and short setup time. Furthermore, the company has introduced automated equipment such as CCD automatic inspection and packaging integrated machines, which have significantly improved product inspection accuracy and packaging efficiency, realizing full-process intelligent management and control from stamping processing to finished product delivery.

"The industry status and technical standards of Frencken Group in the field of high-end precision manufacturing are widely recognized. This cooperation is a high affirmation of our equipment strength and quality control capabilities," said a relevant person in charge of Orienson. In response to Frencken Group's project requirements, the company has established a dedicated production team. Relying on the high precision and high rigidity advantages of Komatsu presses, the team can accurately complete complex stamping processes and control product processing errors within an extremely narrow range. At the same time, an intelligent control system is used to monitor production parameters in real time, ensuring the consistency and stability of product quality. The application of automated equipment has effectively shortened the production cycle, better aligning with Frencken Group's global delivery schedule requirements.

For Frencken Group, this cooperation with Orienson further optimizes its supply chain layout in South China. A person in charge of Frencken Group's Asia-Pacific supply chain stated that Orienson's equipment configuration and technical capabilities can meet the group's customized needs for precision hardware components in fields such as healthcare and semiconductors. Moreover, as a domestic hub for the hardware manufacturing industry, Dongguan boasts a complete industrial support system, which can effectively reduce logistics and collaboration costs and help the group improve product delivery efficiency in the Asia-Pacific region.

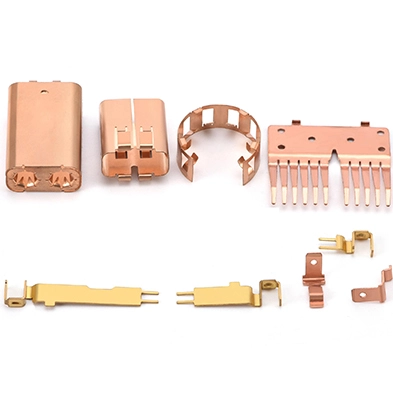

It is revealed that the project under this cooperation mainly covers two types of products: precision elastic components for medical equipment and hardware structural parts for industrial automation equipment, both of which are key supporting components in Frencken Group's core business segments. In the future, the two parties plan to carry out in-depth cooperation in more fields: Orienson will continue to increase investment in equipment upgrades and technological R&D based on the experience accumulated from this high-end project; Frencken Group, on the other hand, will further strengthen its market competitiveness in high-value-added fields by leveraging Orienson's production capacity advantages.

Industry insiders pointed out that the strategic alliance between Orienson and Frencken Group is a typical case of local hardware manufacturing enterprises connecting with the global high-end supply chain. As the hardware industry transitions toward intelligence and precision, such cross-regional and high-standard industrial collaborations will become an industry trend. This not only helps local enterprises enhance their technical capabilities and brand influence but also provides more efficient supporting services for the global high-end manufacturing industry.

English

English