Types of Custom Metal Bending Stamping Parts

2mm Thickness SPCC Metal Stamping with High Quality Precision

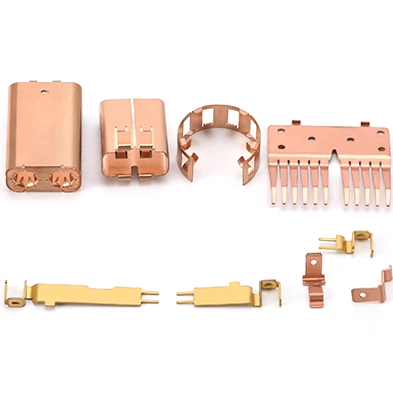

0.6mm Thickness OEM H65 Copper Metal Stamping Bending Parts

0.6mm Thickness OEM H65 Copper Metal Stamping Bending Parts

Material:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200)

Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

1.5mm Thickness Steel Stamping Bending Parts

1.5mm Thickness Steel Stamping Bending Parts

Material:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E)

Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

0.8mm Thickness OEM Copper Alloy Punch Forming Bending Components

0.65mm Thickness H65 Copper Metal Parts for Electrical Accessory

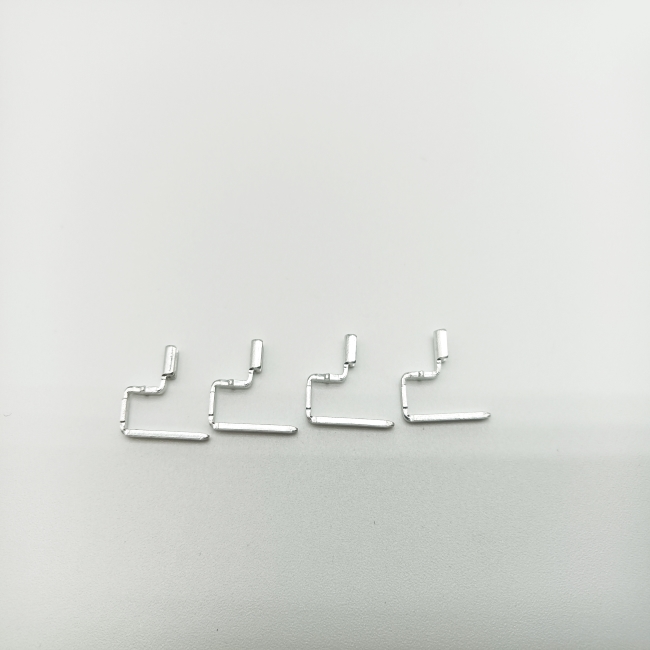

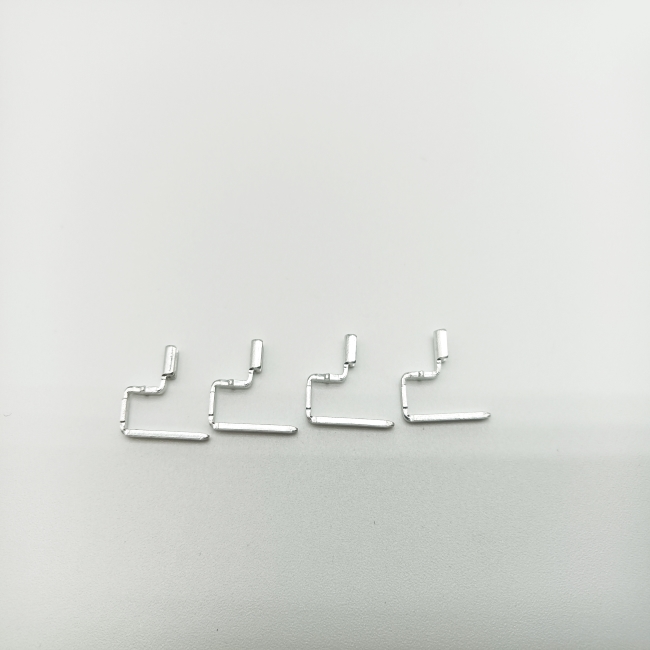

0.46mm Thickness Custom Steel Bending Part

0.46mm Thickness Custom Steel Bending Part

Material:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E)

Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

Benefits of Metal Bending Processes

Metal bending processes offer a number of benefits over other methods of metal fabrication. Some of the key benefits include:

Versatility: Metal bending techniques can be used to produce a wide range of shapes and sizes, making them suitable for a variety of applications in different industries.

Cost-effectiveness: Metal bending processes are generally more cost-effective than other methods of metal fabrication, such as casting or forging.

Precision: Metal bending techniques can produce highly precise and repeatable bends, making them ideal for applications that require high accuracy and consistency.

Efficiency: Metal bending processes are generally faster and more efficient than other methods of metal fabrication, allowing manufacturers to produce large quantities of parts in a relatively short amount of time.

Strength: Metal bending can increase the strength of metal parts by distributing stress more evenly across the part, making it less prone to cracking or breaking under stress.

Customization: Metal bending techniques can be easily customized to meet the specific needs of different applications, allowing manufacturers to produce parts that are tailored to their customer's requirements.

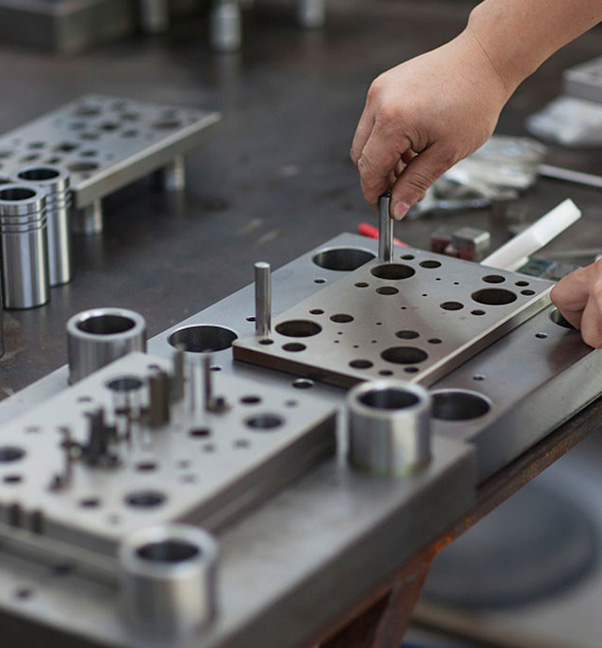

At Orienson, we specialize in custom metal bending and OEM metal stamping. We can provide you with the right solution for your specific application requirements. Our team of experts works closely with customers to understand their needs and develop customized solutions that meet their exact specifications. We use the latest equipment and techniques to ensure that every metal bending part we produce meets the highest standards of quality and durability.

What is Metal Bending?

Metal bending is a manufacturing process that involves deforming a metal workpiece to create a specific shape or angle. The process is used to produce a wide range of metal products, including brackets, frames, enclosures, and other components.

Metal bending can be performed using a variety of techniques, including press braking, roll bending, and tube bending. Press braking involves pressing a metal sheet or plate between a punch and die to create a bend. Roll bending uses a set of rollers to gradually bend a metal workpiece into a specific shape. Tube bending involves bending a metal tube using a mandrel and a set of rollers.

Metal bending is often used in conjunction with other manufacturing processes, such as metal stamping, welding, and machining, to produce complex metal parts with high precision and accuracy. It is a versatile process that can be used with a wide range of metals, including steel, aluminum, copper, and brass.

Metal Bending Parts Techniques

Metal bending can be performed using a variety of techniques, each of which has its own unique advantages and limitations. Some of the most common metal bending techniques include:

Press braking: This technique involves using a press brake to apply force to a metal workpiece, bending it into a specific shape. Press braking is commonly used for bending flat sheets of metal, and is ideal for producing precise, repeatable bends.

Roll bending: Roll bending uses a set of rollers to gradually bend a metal workpiece into a specific shape. This technique is commonly used for bending large sections of metal, such as pipes or beams, and can produce highly accurate, repeatable bends.

Tube bending: Tube bending involves bending a metal tube using a mandrel and a set of rollers. This technique is ideal for producing complex, three-dimensional shapes, and is commonly used in applications such as automotive and aerospace manufacturing.

Rotary draw bending: Rotary draw bending involves clamping a metal workpiece in place and using a rotating die to bend it into a specific shape. This technique is commonly used for producing highly precise, repeatable bends in small-diameter tubes and pipes.

Stretch bending: Stretch bending involves stretching a metal workpiece over a form to produce a bend. This technique is commonly used for producing large, sweeping bends in sheet metal and other thin materials.

Custom Metal Bending Suitable Materials

Custom metal bending parts can be performed on a wide range of materials, including:

Steel: Steel is one of the most commonly used metals for metal bending due to its strength, durability, and versatility. It can be easily bent using a variety of techniques and is suitable for a wide range of applications.

Aluminum: Aluminum is a lightweight, corrosion-resistant metal that is commonly used in the aerospace, automotive, and construction industries. It is easy to bend and can be formed into complex shapes with high precision.

Copper: Copper is a soft, ductile metal that is commonly used in electrical and plumbing applications. Copper stamping parts are easy to bend and can be formed into a wide range of shapes with high precision.

Brass: Brass is an alloy of copper and zinc that is commonly used in decorative and architectural applications. It is easy to bend and can be formed into intricate shapes with high precision.

Stainless steel: Stainless steel is a corrosion-resistant alloy of steel that is commonly used in applications that require high strength and durability. It can be bent using a variety of techniques, but may require more force than other materials.

English

English