What is Metal Stamping?

Ⅰ. What is metal stamping?

Metal stamping is a cold-forming process that makes use of dies and stamping presses to transform sheet metal into different shapes.Pieces of flat sheet metal, typically referred to as blanks, are fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape.Metal stamping products can be used in a variety of industries, such as: autombile、household appliances, etc.

It is a low-cost high-speed manufacturing process that can produce a high volume of identical metal components. Stamping operations are suitable for both short or long production runs, and be conducted with other metal forming operations, and may consist of one or more of a series of more specific processes or techniques, such as: Punching、Blanking、Embossing、Coining、Bending、Flanging.

There are variety of metal stamping techniques that are utilized for particular applications as the following lists:

1. Progressive Die Stamping, this metal stamping technique breaks down the process into a series of stations that each serve a different function. The stock strip carries the part from one station to the next until it is finished and removed from the strip.

2. Transfer Die Stamping, the second type of metal stamping, which similar to progressive die stamping, but a mechanical transport system moves the part from station to station instead of an automated strip.This type of stamping is useful for making parts that need to be free from the metal strip during the stamping process.

3. Fine Blanking, also referred to as fine-edge blanking. This specialty type of metal stamping is ideal for achieving flatness and a full-sheared edge in a way that other metal stamoing techniques cannot.

4. Four-Slide Stamping, also knows as multi-slide stamping, uses four tools simultaneously to from the piece into the proper shape. As the metal sheet is fed through the four-slide, it is quickly bent by each shaft.

As a stamping factory, Orienson has with more than 20 years of experience in precision metal stamping part, progressive die and CNC machining. We focus on the research of fine blanking technology, through the fine blanking process to achieve the stamping without collapsing angle, full bright section and no burr cutting effect, fine blanking surface roughness can be controlled with 0.3um, fine blanking position dimensional accuracy can be controlled within 0.01mm. Moreover, we are also good at designing and manufacturing continuous molds with a length of less than 2 meters and a material thickness of 0.06-6.0mm, mold accuracy can be controlled within 0.005mm. According to customer needs to develop automatic die tapping, die automatic riveting, die automatic welding, robot feeding and other automatic production process.

Typically, metal stamping takes cold metal and places it between dies, although some processes use heated material. Pressed material forms the metal into the desired shape. Often, these shapes create tools or components for larger creations. Sometimes, some in the manufacturing industry may refer to metal stamping as pressing.

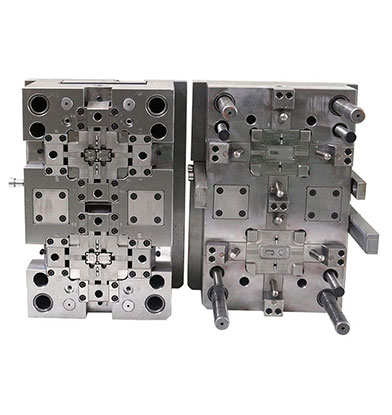

Stamping dies within the machine either cut metal or form it. These molds have specific designs for each project. While it takes a while to make a mold, once the mold is complete, the stamping process happens quickly.

This process allows the production of large numbers of identical parts. Stamping may be one step in the creation of many parts, or it may be the only step. Stamping, blanking, embossing, flanging, bending and embossing are some of the stages a metal may go through during the stamping process.

The versatility of stamping makes it an ideal production method for industries such as automotive, military, mass transit and manufacturing, as well as many others.

Ⅱ. Stamping type

The type of punch used depends on the desired finished product. Precision, hot metal and progressive die are some of the most commonly used stamping processes.

1. Precision metal stamping

Precision stamping produces raised images or 3D parts and produces finished products with tight tolerances. Compared to other forms of stamping, precision stamping involves less material movement between machines, which makes the process faster.

The high precision of this stamping method allows the formation of complex designs that must strictly adhere to their specifications. You can use precision stamping on components with length tolerances of 0.001 to 0.002 inches and roundness tolerances of 0.0005 to 0.001 inches. Aircraft components, engine components, electronics, telecommunications equipment and prototypes are often made using precision metal stamping.

A variation of this process is micro-precision stamping. This method enables the fabrication of complex parts for the electronics or medical industries that are as thin as 0.002 to 0.005 inches thick.

2. Progressive metal stamping

Progressive stamping, also known as progressive die stamping, moves a piece of metal through multiple stations, each of which performs a separate operation on the metal. During these various stages, the sheet metal remains attached to the long strip of material. The final machine cuts the finished product from the metal strip.

Progressive die stamping is an excellent choice when choosing a manufacturing method for long-term processes that require high volume production. The mold lasts a long time and the process generates minimal waste.

When creating larger parts that may require a different press, you will need to stamp with a transfer die. This process differs from progressive stamping in only a few small ways. The workpiece is separated from the metal belt earlier, and the conveyor belt transfers the workpiece from machine to machine.

English

English