Power Precision: How Copper Stamping Parts Drive Breakthroughs in Energy Development

In the fast-paced world we live in, energy demands are constantly increasing. As a result, there is an urgent need to find innovative solutions that can cater to these growing requirements. One such solution lies in the use of copper stamping parts, which play a crucial role in driving breakthroughs in energy development. In this blog, we will explore the importance of copper stamping parts and their impact on the power industry.

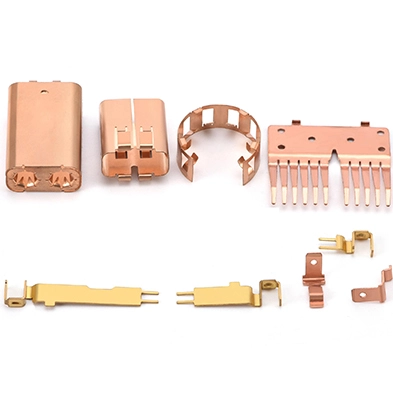

What are Copper Stamping Parts?

Copper stamping parts refer to metal components made from copper that are used in various industries, including energy production. These parts are created using precision stamping techniques, which involve the fabrication of intricate shapes and designs. Copper stamping parts are known for their durability, conductivity, and resistance to corrosion, making them perfect for applications in energy development.

The Significance of Copper Stamping Parts in Energy Development

Electrical Conductivity

Copper is renowned for its excellent electrical conductivity. This property makes copper stamping parts highly efficient in conducting electricity, making them ideal for use in electrical systems. From power generation to transmission and distribution, copper stamping parts ensure minimal energy loss and improved efficiency.

Thermal Conductivity

In addition to its electrical conductivity, copper also possesses remarkable thermal conductivity. The ability to efficiently transfer heat is crucial in energy development processes such as power generation, where excess heat can decrease overall efficiency. Copper stamping parts aid in maintaining optimal temperatures, thereby maximizing energy output.

Reliable Performance

Copper stamping parts are known for their reliability and durability. These components are designed to withstand harsh operating conditions, such as high temperatures and heavy loads. Their resilience ensures uninterrupted energy production, minimizing downtime and maximizing productivity.

Corrosion Resistance

The energy industry often operates in demanding environments, with exposure to moisture, chemicals, and other corrosive elements. Copper stamping parts possess exceptional corrosion resistance, making them suitable for long-term use in challenging conditions. This resistance to corrosion contributes to the longevity and reliability of energy generation processes.

Applications of Copper Stamping Parts in Energy Development

Power Generation

Copper stamping parts are extensively used in power generation equipment, including turbines, generators, and transformers. Their excellent electrical and thermal conductivity ensures efficient energy conversion and transmission.

Renewable Energy

The growing focus on renewable energy sources such as solar and wind power has increased the demand for copper stamping parts. These components are vital in the production and distribution of renewable energy, facilitating the conversion and storage of power.

Electrical Grids

Copper stamping parts play a critical role in electrical grids, including substations and distribution systems. Their high conductivity and reliability are essential for delivering electricity safely and efficiently to consumers.

The Future of Copper Stamping Parts in Energy Development

As energy demands continue to rise, the importance of copper stamping parts in energy development will only grow. With ongoing advancements in technology and the increasing adoption of renewable energy, the need for reliable and efficient components like copper stamping parts will become even more significant. These parts will continue to drive breakthroughs in power precision, ultimately shaping the future of energy production.

In conclusion, copper stamping parts are vital components in energy development, driving breakthroughs in power precision. Their excellent electrical and thermal conductivity, reliability, and corrosion resistance make them ideal for use in power generation, renewable energy, and electrical grids. As the energy industry evolves, copper stamping parts will play an increasingly important role in meeting the growing demands for efficient and sustainable energy solutions.

English

English