Analysis on Blank Holder Force, Back Pressure and Edge Value of Fine Blanking

The pressing force in fine blanking should not be too small

During fine blanking, V-shaped gear ring press plates are often used for strong pressing. The function of the V-shaped gear ring press plate is:

Clamping the material and keeping it perpendicular to the stamping direction during fine blanking, preventing it from curling up.

Providing strong pressure, establishing a three-directional compression stress state in the deformation area, eliminating or preventing the generation of cracks caused by tensile stress, and preventing a tearing of the cutting surface.

To ensure the quality of the stamped parts, reduce power consumption, and extend the service life of the mold, the pressing force needs to be calculated and set correctly. If the pressing force is too small, the static hydrostatic pressure stress of the material in the deformation area is low, which is not conducive to suppressing cracks and can lead to tearing on the cutting surface, affecting the quality of the cutting surface. If the pressing force is too large, it will generate excessive power consumption, make the mold structure complicated, and reduce the service life of the mold. Therefore, the pressing force needs to be adjusted in actual production processes.

The counter pressure in fine blanking should not be too small

The counter pressure is an important factor that affects the quality of the fine blanking parts. A larger counter pressure can increase the compression stress of the material in the deformation area, suppress tensile cracks, and help improve the quality of the fine blanking parts. However, if the counter pressure is too large, it can increase the load on the convex die and reduce the service life of the stamping die.

If the counter pressure is too small, it can affect the dimensional accuracy, flatness, collapse angle, and cutting surface quality of thestamped part. If the counter pressure is smaller, the fine blanking part will have a larger collapse angle, and the surface of the stamped part will not be flat and will be raised in the middle. Therefore, similar to the pressing force, the counter pressure also needs to be appropriately adjusted in actual production processes while ensuring the quality of the stamped parts.

The overlap value of fine blanking should not be too small

Because during fine blanking, the gear ring press plate needs to clamp the material, and the shape of the gear makes the overlap value of fine blanking larger than that of ordinary stamping. The layout design of fine blanking is similar to that of ordinary stamping in principle, and the correct selection of the overlap value of fine blanking has a great impact on the quality of the fine blanking parts. Generally speaking, the larger the overlap value, the better the quality of the cross-section of the fine blanking, but it is not economical.

Therefore, when selecting the overlap value for fine blanking, the smallest value should be chosen under the condition of ensuring the quality of the cutting surface to maximize the utilization value of the material.

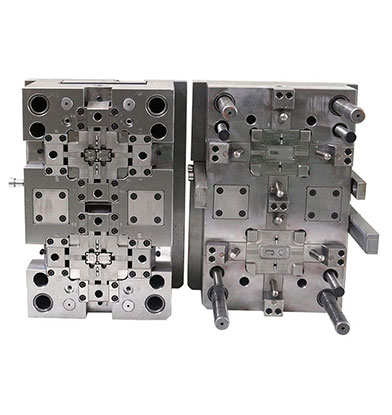

The typical structures of fine blanking molds include structures with movable convex dies, structures with fixed convex dies, and continuous fine blanking molds. The fine blanking process requires precise punching force, pressing force, and counter pressure.

Therefore, fine blanking machines are generally used for mass production of fine blanking parts, but the equipment investment cost is high. Therefore, many manufacturers use hydraulic frames to precision blank parts on hydraulic presses. Although the cost of a hydraulic press is low, it is suitable for the production of fine blanking parts with low added value and relatively low precision and production efficiency.

English

English