Why Quality Matters: Selecting a Trusted Deep Drawing Parts Company

When it comes to deep drawing parts, quality is a non-negotiable factor. The precision and reliability of these components are critical for various industries, and choosing the right deep drawing parts company can make all the difference. In this article, we'll explore the significance of quality in deep drawing and why selecting a trusted and reliable company is essential.

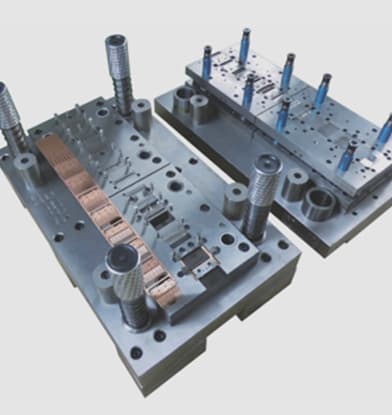

Understanding Deep Drawing Parts

Deep drawing is a metal forming process that transforms flat metal sheets into three-dimensional components. This process is widely used in manufacturing industries, including automotive, aerospace, medical, and electronics, to create parts that require complex shapes, high precision, and structural integrity. These parts play crucial roles in numerous applications, from critical components in aircraft to medical devices and electronic equipment.

The Significance of Quality in Deep Drawing

Quality in deep drawing parts is vital for several reasons:

Precision Matters

Precision is the hallmark of deep drawing. Components manufactured through deep drawing are often required to meet tight tolerances and exact specifications. Any deviation from these requirements can lead to compromised product performance and safety. Therefore, a trusted deep drawing parts company is one that can consistently deliver precise components.

Structural Integrity

Many deep drawn parts are critical for the structural integrity of a final product. For instance, in the aerospace industry, components like fuel system parts and hydraulic reservoirs must withstand extreme conditions. A minor flaw in the deep drawing process can lead to catastrophic consequences. Quality deep drawing ensures that parts are structurally sound and capable of performing under demanding conditions.

Longevity and Reliability

Deep drawn parts are often designed to have a long service life. In the automotive industry, body components and engine parts must endure years of wear and tear. Quality parts not only function as intended but also maintain their performance and reliability over time, reducing maintenance costs and ensuring safe operation.

Minimizing Waste and Costs

Quality deep drawing processes result in minimal waste. This not only contributes to the cost-effectiveness of the production process but also aligns with sustainability goals. Reducing waste minimizes the environmental impact of manufacturing, making quality a crucial aspect of responsible production.

Selecting a Trusted Deep Drawing Parts Company

When selecting a deep drawing parts company, several factors contribute to trustworthiness and quality:

Experience and Expertise

Look for a company with a long-standing reputation and a team of experts who understand the intricacies of deep drawing. Experience often translates to better quality and performance.

Quality Control Measures

A trusted company will have stringent quality control measures in place, ensuring that every part produced meets the required specifications and standards.

Customer References

Seek customer references and testimonials to gauge the reputation of the company. Companies with a track record of satisfied customers are more likely to deliver quality.

Compliance with Industry Standards

Ensure that the company adheres to industry standards and regulations, especially if you're working in a highly regulated sector such as aerospace or medical.

The quality of deep drawing parts is integral to the success and safety of various industries. Components manufactured through deep drawing play critical roles in automotive, aerospace, medical, electronics, and many other sectors. Quality ensures precision, structural integrity, longevity, and sustainability in the production of these components. Therefore, when selecting a deep drawing parts company, prioritize trustworthiness, experience, quality control, and adherence to industry standards. Quality is not just a preference; it's a necessity for the success of your projects and the safety of your end-users.

English

English