Is Stainless Steel Hard to Stamp? A Deep Dive into Challenges and Solutions

1. Understanding Stainless Steel in Stamping

Stainless steel’s reputation for durability and corrosion resistance makes it a top choice for metal stamping, yet its hardness poses unique challenges. This article explores why stainless steel can be difficult to stamp, its bending versus snapping behavior, and strategies to overcome these hurdles. Ideal for engineers and manufacturers, this guide provides technical insights to optimize your stamping process.

2. Why Stainless Steel Poses Stamping Challenges

Stainless steel’s high chromium content (10-20%) forms a protective oxide layer, enhancing corrosion resistance but increasing hardness. This requires greater force and precise die design, especially for grades like 304 or 316, which vary in formability. Its tight forming nature can lead to tool wear or material cracking if not handled correctly.

3. Physical Properties of Stainless Steel

Does Stainless Steel Snap or Bend?

Stainless steel’s behavior depends on its grade and treatment. Austenitic grades (e.g., 304) are ductile, bending easily with cold working, while martensitic grades (e.g., 420) are brittle, prone to snapping under stress. Heat treatment or cold working adjusts its hardness, influencing stamping outcomes.

Comparing Grades for Stamping Ease

Austenitic stainless steel, with lower carbon, suits deep drawing for sinks or fryers, offering stretchability. Martensitic grades, harder and brittle, are better for cutting tools, requiring different stamping techniques. Understanding grade-specific properties is crucial.

4. Overcoming Stamping Difficulties

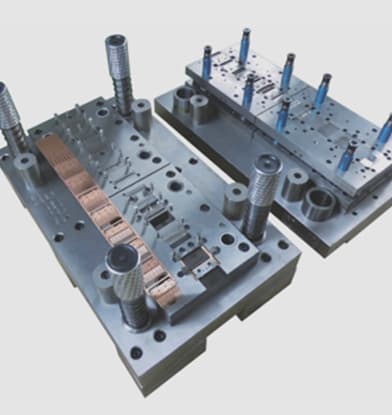

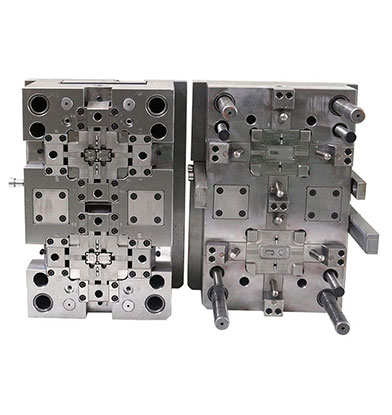

Optimizing Die Design and Tools

Using hardened steel or carbide dies with proper clearances reduces wear and prevents cracking. Lubrication minimizes friction, ensuring smooth forming of stainless steel components.

Adjusting Stamping Techniques

Progressive die stamping with multiple stages allows gradual shaping, reducing stress on stainless steel. Controlled force and annealing between steps enhance formability.

Material Preparation

Annealing stainless steel to a dead-soft state improves ductility, making it easier to stamp. Post-stamping heat treatment can restore strength without compromising shape.

Grade

Formability

Common Application

Stamping Tip

|

|

|

|

304 (Austenitic) | High | Kitchen sinks | Use annealing |

316 (Austenitic) | Moderate | Marine parts | Apply lubrication |

420 (Martensitic) | Low | Cutting tools | Avoid deep drawing |

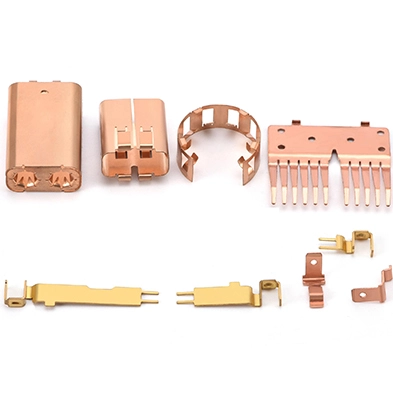

5. Practical Applications and Industry Insights

Industries Relying on Stainless Steel Stamping

Medical devices, automotive exhausts, and food processing equipment benefit from stainless steel’s hygiene and durability, driving demand for effective stamping solutions.

Case Studies of Successful Stamping

Examples include stamped surgical instruments and exhaust components, where tailored techniques overcame hardness challenges, ensuring precision and strength.

6. Insight: Oriensonmetal’s Expertise in Stainless Steel Stamping

At Oriensonmetal, we recognize stainless steel stamping as a test of precision and innovation. With years of industry leadership, we’ve honed techniques to tackle its hardness, mastering grades like 304 and 316 for complex medical and automotive parts. Our expertise lies in custom die design, leveraging advanced materials to minimize wear while maximizing formability. We’ve developed proprietary lubrication methods and multi-stage stamping processes to prevent cracking, ensuring consistent quality even with martensitic grades. Our focus on client collaboration allows us to adapt to unique project needs, from prototyping to mass production. Oriensonmetal’s commitment to pushing stamping boundaries reflects our dedication to delivering durable, high-performance stainless steel components that meet global standards, setting us apart in the field.

7. Conclusion: Mastering Stainless Steel Stamping

Stainless steel’s hardness makes it challenging to stamp, but with optimized dies, techniques, and material preparation, these obstacles can be overcome. Whether it bends or snaps depends on the grade, offering opportunities for tailored applications. Embrace these strategies to unlock stainless steel’s full potential in your stamping projects.

English

English